Tungsten .

1000.00 - 3500.00 INR

Product Details:

- Thickness 0.1 mm to 100 mm (varies by product form)

- Hardness Mohs: 7.58.0

- Tensile Strength 600800 MPa (depending on grade and form)

- Thermal Conductivity 170 W/mK

- Product Type Tungsten

- Types of Alloy Pure Tungsten (can be doped with La, Ce, Th, etc.)

- Material Tungsten

- Click to View more

X

Tungsten . Price And Quantity

- 1000.00 - 3500.00 INR

- 100 Kilograms

Tungsten . Product Specifications

- 19.3 Gram per cubic centimeter(g/cm3)

- High Mechanical Strength

- W1, W2, WL10, WL20

- Mohs: 7.58.0

- Silver Gray

- 3422C

- Pure Tungsten (can be doped with La, Ce, Th, etc.)

- Tungsten

- 0.1 mm to 100 mm (varies by product form)

- Tungsten

- Excellent Corrosion and High Temperature Resistance

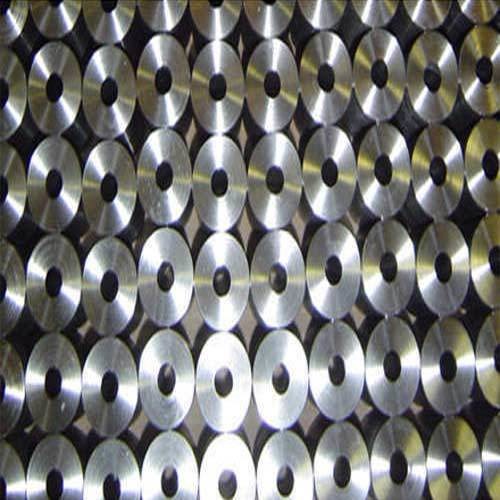

- Bar, Rod, Sheet, Wire, Plate

- W 99.95%

- 170 W/mK

- 600800 MPa (depending on grade and form)

Tungsten . Trade Information

- Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 500 Kilograms Per Month

- 2-3 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Eastern Europe, Middle East, Western Europe

- All India

Product Description

Tungsten offered by us is a gleaming white metal that is pliable and easy to work within its purest state. It has good corrosion resistance and is unaffected by nitric, hydrofluoric, or sulphuric acid solutions. This metal is very effective as well as economical and safe to use. Our provided Tungsten is used as an additive in specialty alloys, automotive parts, aerospace components, electrical and electronic appliances, and other end-uses. It is the purest form of pure metal. This has the lowest vapor pressure.Precision Engineering for Demanding Industries

Tungstens unique combination of strength, high melting point, and superior conductivity makes it a material of choice in advanced fields such as aerospace, electronics, and medical technology. Its versatility in various shapes and finishes ensures compatibility with diverse technical requirements, supporting innovation and reliability in critical applications.

Various Forms and High Purity Standards

Our tungsten products are offered in different forms, including rods, plates, wires, and sheets, with thickness ranging from 0.1 to 100 mm. Manufactured to meet ASTM international standards with 99.95% purity, they provide consistent quality for high-precision uses, from industrial to medical environments.

FAQs of Tungsten .:

Q: How is tungsten commonly used in the electronics and lighting industries?

A: Tungstens excellent electrical conductivity and high melting point make it ideal for filaments, contacts, and electrodes in electronic components and lighting products, where durability and heat resistance are essential.Q: What are the benefits of using high-purity tungsten (99.95%) in medical devices?

A: High-purity tungsten ensures minimal contaminants, offering biocompatibility, stable performance, and resistance to corrosion, which are critical qualities for sensitive medical and scientific instruments.Q: When should I choose forged, polished, or ground surface finishes for tungsten products?

A: The choice depends on your applications requirementspolished finishes suit aesthetic or low-friction needs; ground finishes provide tight dimensional tolerances; forged surfaces are optimal where maximum material integrity is needed.Q: Where are tungsten alloys with additives like La, Ce, or Th commonly applied?

A: Tungsten alloys doped with elements such as lanthanum, cerium, or thorium are often used in specialized electrodes, high-temperature environments, and applications demanding enhanced machinability or emission characteristics.Q: What process ensures the consistent quality of your tungsten materials?

A: Our tungsten products are manufactured under strict quality control, adhering to ASTM B760, ASTM F288, and ASTM B386 standards, ensuring high purity, mechanical strength, and uniform properties for end users.Q: How does tungstens high density and mechanical strength benefit advanced applications in aerospace?

A: Its density (19.3 g/cm) and mechanical strength support structural components, counterweights, and radiation shielding in aerospace, offering efficiency, safety, and durability where weight and space must be optimized.Q: What packing options are available for tungsten shipments?

A: Tungsten products are securely packed in wooden cases, cartons, or as specified by the customer, ensuring safe transport and integrity upon delivery, whether for export, import, or local supply.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Minor Metal Products' category

|

METAL ALLOYS (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |